I recently had the pleasure of joining Evan Davis on the Decisions That Made Me podcast, a mini-series from the creators of The Bottom Line. The episode focused on one of the most pivotal decisions in my career: the choice to buy a failing factory and bring Trunki’s production back to the UK. This bold move, which carried significant risks, ultimately played a crucial role in shaping Trunki’s future.

A Journey Into Product Design

The conversation began with my journey into product design. Growing up with undiagnosed dyslexia and cystic fibrosis (CF), I faced unique challenges that steered me toward creative problem-solving. A chance encounter with a product design book as a teenager sparked my passion, leading me to pursue design at Northumbria University. It was there that the idea for Trunki—a ride-on suitcase for kids—was born during a national luggage design competition.

The Dragons’ Den Turning Point

Evan and I revisited my infamous Dragons’ Den appearance, where Trunki was rejected. Despite the public critique, the episode brought invaluable attention, turning what seemed like a failure into a launchpad. The rejection, while tough, became a lesson in resilience: setbacks can often be the catalyst for success when approached with the right mindset.

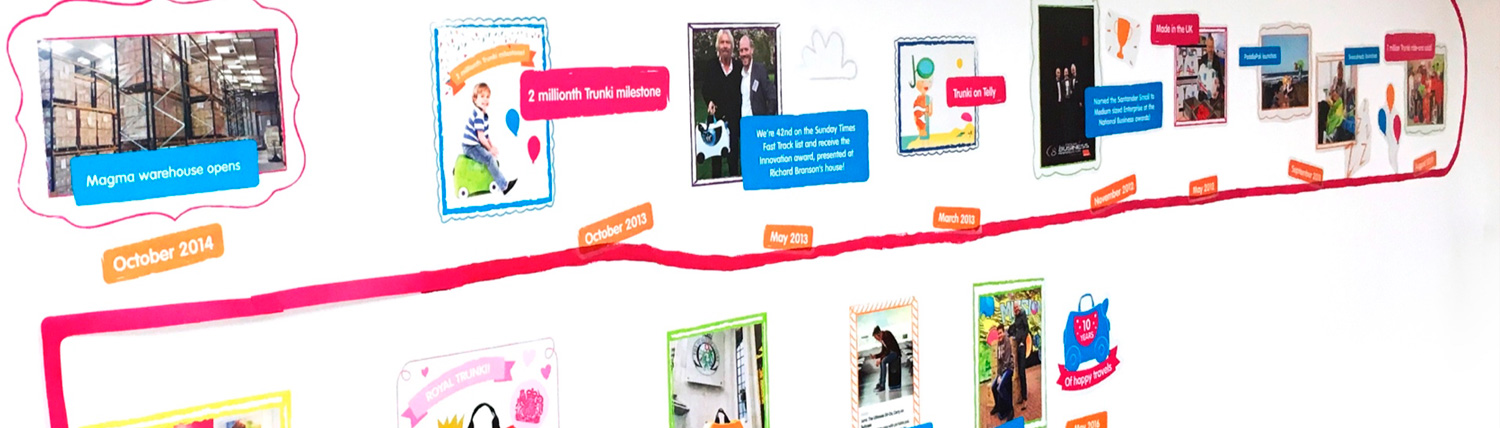

The Decision to Buy Magma Moulding

In 2012, I faced a critical moment when Magma Moulding, the UK factory producing Trunki cases, was on the brink of liquidation. The factory had struggled with scaling up to meet demand, and their inefficiencies jeopardized our supply chain. I was left with a pivotal decision: move production back overseas or buy the factory and take control of our manufacturing.

This decision not only aligned with my vision of sustainability but also positioned me as a British manufacturing speaker. I often share insights on how reshoring production and investing in local manufacturing can drive business growth while reducing environmental impact.

Turning Chaos Into Opportunity

The early days of running Magma Moulding were far from smooth. As detailed in the Cash and Copies chapter of my book, the factory was plagued with inefficiencies and low morale. Employees were disillusioned, processes were chaotic, and the night shift was often producing more waste than usable products.

Through a combination of leadership changes, process improvements, and aligning the team around a shared vision—“Proud to Manufacture in the UK”—we gradually turned the factory around. This experience has since become a cornerstone of my work as a UK manufacturing keynote speaker, highlighting the benefits of local production and the resilience it builds within a business.

The Long-Term Payoff

The decision paid dividends during two major crises:

- Brexit: Currency fluctuations made UK manufacturing more cost-effective.

- COVID-19: When global supply chains faltered, having local production allowed us to meet demand swiftly without exorbitant shipping costs.

These experiences underscore why I’m passionate about being a speaker on reshoring production, sharing how businesses can future-proof their operations by investing in local supply chains.

Lessons for Aspiring Entrepreneurs

Here are some lessons from this journey:

- Trust Your Instincts: Bold decisions often face skepticism, but they can yield significant rewards when driven by conviction and strategic thinking.

- Turn Chaos Into Opportunity: Operational inefficiencies are not roadblocks but opportunities to innovate and improve.

- Invest in Culture: Aligning your team around a shared vision can transform morale and drive long-term success.

- Future-Proof Your Business: Owning your supply chain provides flexibility and resilience during external disruptions.

Listen to the Full Episode

For a deeper dive into these challenges and decisions, listen to the full episode here: Decisions That Made Me: Rob Law.

Thank you to Evan Davis and the Decisions That Made Me team for having me. I hope this episode inspires entrepreneurs to embrace bold decisions and turn challenges into opportunities.